Moving towards circular targets

with full scale production of recycled EPS in Norrköping WATCH THE VIDEO

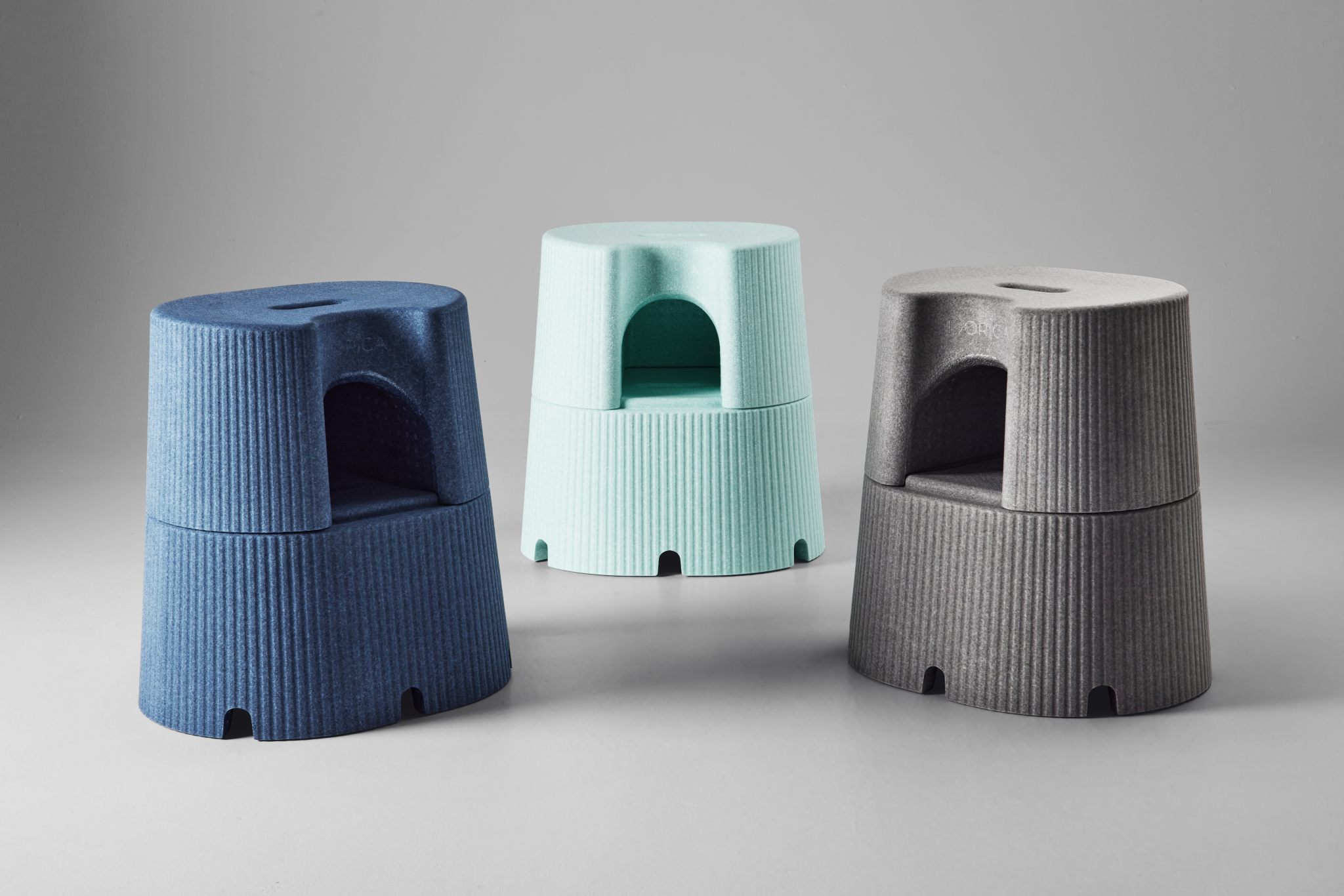

Closing the circular loop

BEWI’s circular hub in Norrköping supports higher recycled content in the product offering

Now in full scale production, BEWI’s circular hub in Norrköping, Sweden – the first of its kind in the country – increases the company’s expanded polystyrene (EPS) recycling capacity by 40 per cent. With this step, BEWI strengthens its position as a leader in circular solutions for EPS.

Read more